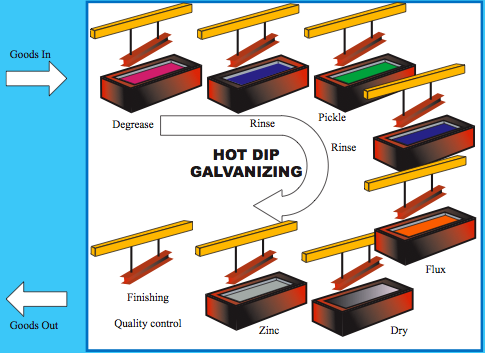

Process Diagram

|

Chemical preparation of surfaces to be hot dip galvanized is made in a semi-automated pre-treatment line. |

|

|

|

The final immersion is done into a kettle containing some 350 tons of zinc and micro-alloy elements, at a temperature of 450° ±1°C. |

By the procedures prescribed, Durozinq® Technology,

guarantees the quality of the corrosion protection of galvanized surfaces.

The controlled thickness

of the Zn layer is

80 - 250 microns

for parts with a

Silica-content within

0,03% - 0,15%

The raw materials are acquired from well-established market leading suppliers, thus guaranteeing the franchise-prescribed quality requirements.